Our Services:

plastic injection molding projects from prototype to production

Our Services

-

High-Volume, Custom Plastic Injection Molding

Experience precision and efficiency with Elite Plastic Products. Our state-of-the-art facility boasts 29 plastic injection molding machines, cutting-edge technology, and over 30 years of industry expertise. Our 110-400 ton presses make us the perfect solution for your high-volume plastic injection molding needs.

Tool Transfer Expert

Systematic Molding Process

-

Global & In-House Tooling

At Elite, we bring you the best of both worlds. Our global tooling capabilities provide competitive pricing, while our in-house tooling department ensures molds are built to North American standards.

Asian & Domestic tool construction

Engineering assistance

In-House Tool Maintenance & Engineering Changes

-

Automation

Elevate your molding experience with Elite's commitment to world-class services and fully automated processes. Our End-of-Arm and full automation cells reduce labor requirements, providing efficient and cost-effective solutions.

Overmolding

Insert Molding

Assembly

.

full Lifecycle management for your next project

Quality Assurance

Elite is committed to continual improvement in all aspects of our business. With real time shop floor communication, 100% traceability from raw material through shipment, and IATF certified production processes, we promise nothing but the best quality for our customers.

-

Thorough APQP process to capture all customer requirements (fully integrated into manufacturing ERP system)

Monitor key process indicators in all business areas including customer service, machine and tooling maintenance, and on-time PPAP submissions

Investment in automation equipment and employee training

Performance Testing

We go the extra mile on our performance testing protocols to ensure our products are built to last. Our in-house testing capabilities and management of outsourced testing guarantee products built to last, providing our customers with peace of mind.

-

Measurement and Part Performance Testing

Part Inspection and Statistical Process Control (SPC)

Process Capability Studies

Measurement System Analysis

Sample Inspection (full dimensional, first/last piece, in-process inspection)

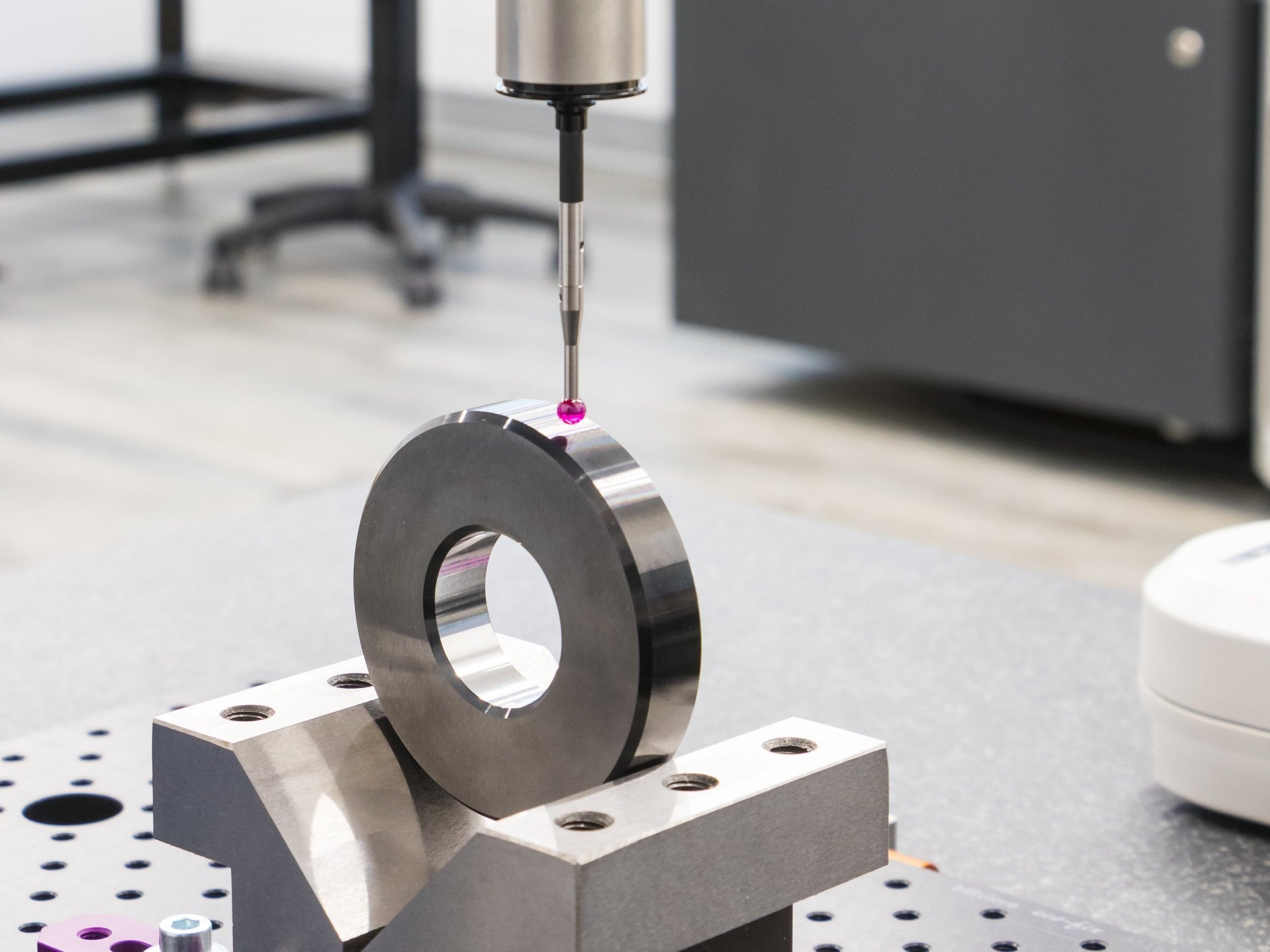

Full Service Metrology

We pride ourselves on being on the cutting edge of technological advancements. Our full-service metrology lab is designed to ensure your product is built to North American standards.

-

Contact & Non-Contact CMM

FARO Arm

Surface Profilometer

Force Gage

Spectrophotometer

Gloss Meter

Torque Driver

Calipers, gage pins, height gage, surface plate

Design and manufacture of gages, check fixtures, assembly fixtures

100% integration with ERP system

Engineering Services

Our dedicated, on-staff engineers will work with you every step of the way, from prototype to production line and beyond. Let’s collaborate to develop your designs, troubleshoot issues, and bring your idea to life.

-

Mold Flow Analysis, 2D, & 3D Design

Molding Process Development and Troubleshooting

On-Site Customer Support for Tooling and Processing

Reverse Engineer Existing Parts

DFM Analysis

3D Printing (DLS & SLA)

In-House and Third-Party Part Testing

Production Feasibility Reports

Customer Support

Elite’s team is dedicated to understanding our customers needs. Each of our customers receives a dedicated project manager and weekly production reports to keep your project on track and on time. Your success is our success.

-

A dedicated program manager

A project timeline and weekly tool build report

Support for pre-launch quantities at production pricing

Competitive pricing

PPAP qualifications

CMM layouts

Thorough APQP process to capture all customer requirements with on time delivery